Maximum Payload Capacity

In the realm of heavy-duty transportation and logistics, understanding the concept of maximum payload capacity is essential. This term, often abbreviated as MPC, plays a pivotal role in ensuring the efficient and safe operation of various vehicles and equipment. Whether it's a cargo ship navigating the high seas or a delivery truck weaving through city streets, the maximum payload capacity is a critical factor that dictates performance, compliance, and overall operational success.

This comprehensive guide aims to delve into the intricacies of maximum payload capacity, exploring its definition, calculation, and its practical implications across different industries. By the end of this article, you'll have a deep understanding of how MPC influences vehicle performance, and you'll learn strategies to optimize payload while adhering to safety standards.

Defining Maximum Payload Capacity

Maximum payload capacity, in its simplest terms, refers to the maximum weight or load that a vehicle, vessel, or machine can safely carry. It is a critical specification that determines the practical limits of a transportation asset, ensuring it operates within safe and legal boundaries.

The concept of MPC is not exclusive to a single industry. It is a fundamental consideration in maritime shipping, aviation, road transportation, and even construction equipment. In each of these sectors, the MPC influences operational decisions, from route planning to equipment maintenance and staffing requirements.

Calculating Maximum Payload Capacity

The calculation of maximum payload capacity is a precise and complex process, involving various factors unique to each type of vehicle or equipment. Here’s a simplified breakdown of the key considerations:

Vehicle or Equipment Specifications

The starting point for determining MPC is understanding the inherent capabilities of the vehicle or equipment. This includes the engine power, tire specifications, suspension design, and frame strength. Each of these components contributes to the overall carrying capacity of the vehicle.

Load Distribution

The distribution of weight across the vehicle is critical. An unevenly distributed load can lead to instability and safety hazards. Proper load distribution ensures that the vehicle’s performance is optimized and that wear and tear on specific components is minimized.

Road or Route Conditions

The environment in which the vehicle operates significantly influences its MPC. Steep gradients, uneven surfaces, and weather conditions can all impact the vehicle’s ability to carry heavy loads safely. For instance, a truck navigating a mountainous terrain may have a lower MPC compared to one traveling on a flat highway.

Legal and Safety Regulations

Governing bodies in various industries set legal limits on maximum payload capacities to ensure public safety. These regulations often consider the vehicle’s type, size, and intended use. Exceeding these limits can result in fines, vehicle impoundment, or even legal consequences.

| Vehicle Type | Maximum Payload Capacity |

|---|---|

| Standard Pickup Truck | 1,000 - 1,500 lbs |

| Large Commercial Truck | 80,000 lbs (varies by jurisdiction) |

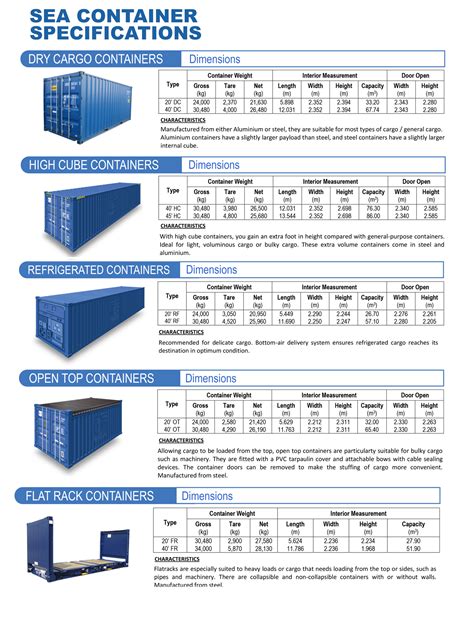

| Cargo Ship (Bulk Carrier) | Up to 300,000 DWT (Deadweight Tons) |

| Aircraft (Cargo) | Varies widely based on aircraft model and configuration |

The Impact of Maximum Payload Capacity

Maximum payload capacity is a critical factor that influences a wide range of operational aspects. Understanding its implications is key to optimizing fleet performance and ensuring compliance.

Operational Efficiency

Vehicles operating at their MPC are generally more fuel-efficient and cost-effective. However, it’s a delicate balance, as exceeding the MPC can lead to increased fuel consumption, wear on components, and potential safety risks.

Compliance and Safety

Adhering to MPC regulations is not just a legal requirement; it’s a matter of safety. Overloading vehicles can lead to tire blowouts, brake failure, and structural damage, endangering both the driver and other road users.

Fleet Management and Maintenance

Fleet managers use MPC data to plan routes, assign loads, and schedule maintenance. Regularly monitoring MPC helps identify vehicles that consistently operate at or near capacity, which may require more frequent inspections or upgrades.

Economic Considerations

In the transportation industry, maximizing payload while adhering to MPC regulations can significantly impact a company’s bottom line. Efficient payload management can lead to cost savings, increased productivity, and improved customer satisfaction.

Strategies for Optimizing Maximum Payload Capacity

Maximizing payload capacity without compromising safety is a delicate balance. Here are some strategies that professionals in the transportation industry employ to achieve this goal:

Vehicle Selection and Upgrades

Choosing the right vehicle for the job is critical. Fleet managers often select vehicles with specifications that align closely with the intended use, ensuring the MPC is suitable for the expected loads.

Additionally, upgrades such as high-performance tires, reinforced suspension systems, or customized body designs can enhance a vehicle's MPC and its ability to handle heavy loads.

Load Planning and Distribution

Efficient load planning is key to optimizing MPC. This involves strategic placement of cargo to ensure even weight distribution and minimize the risk of overload. Specialized software tools can assist in this process, providing insights into optimal cargo placement.

Route Optimization

The choice of route can significantly impact MPC. Fleet managers consider factors like road conditions, gradient profiles, and weather forecasts when planning routes. Avoiding steep hills or rough terrain can help maintain MPC and reduce the risk of overloading.

Driver Training and Awareness

Educating drivers about the importance of MPC and how it affects vehicle performance and safety is crucial. Well-trained drivers can make informed decisions about load acceptance, route planning, and overall vehicle management.

Regular Vehicle Maintenance

Routine maintenance ensures vehicles are in optimal condition to handle their MPC. This includes regular inspections, tire replacements, brake checks, and suspension adjustments. Well-maintained vehicles are less likely to experience issues with payload capacity.

Utilizing Technology

Advanced technologies like telematics and GPS tracking can provide real-time data on vehicle performance, load distribution, and route efficiency. This data can be used to make informed decisions about MPC optimization and fleet management.

Future Implications and Innovations

The transportation industry is constantly evolving, and the concept of maximum payload capacity is no exception. As technology advances and regulations adapt, we can expect to see significant changes and innovations in this field.

Autonomous Vehicles and MPC

The rise of autonomous vehicles presents a unique opportunity to optimize MPC. These vehicles, equipped with advanced sensors and algorithms, can dynamically adjust their payload based on real-time road conditions, weather, and traffic patterns. This level of precision can lead to significant improvements in fuel efficiency and overall performance.

Advanced Materials and Vehicle Design

Innovations in materials science are leading to the development of lighter, stronger vehicle components. For instance, the use of composite materials in truck beds or carbon fiber in aircraft structures can reduce vehicle weight, allowing for increased payload capacity without compromising safety.

Data-Driven Decision Making

The transportation industry is increasingly leveraging big data analytics and machine learning to optimize operations. By analyzing vast amounts of data on vehicle performance, route conditions, and payload management, companies can make more informed decisions about MPC, leading to improved efficiency and reduced operational costs.

Regulatory Changes and Industry Standards

Regulatory bodies are continually reviewing and updating MPC guidelines to ensure safety and efficiency. These changes can impact everything from vehicle design to operational practices. Staying abreast of these updates is crucial for transportation companies to remain compliant and competitive.

Conclusion

Understanding and optimizing maximum payload capacity is a critical aspect of transportation and logistics management. It involves a delicate balance of vehicle capabilities, route conditions, and legal regulations to ensure efficient, safe, and compliant operations.

By embracing technological advancements, data-driven decision-making, and innovative vehicle designs, the transportation industry can continue to push the boundaries of MPC, leading to increased efficiency, reduced costs, and enhanced safety. As we look to the future, the potential for further optimization and innovation in this field is indeed promising.

What is the maximum payload capacity of a standard pickup truck?

+A standard pickup truck typically has a maximum payload capacity of around 1,000 to 1,500 lbs. However, this can vary based on the specific make and model of the truck.

How does maximum payload capacity affect fuel efficiency?

+Operating at or near the maximum payload capacity can impact fuel efficiency. Overloading a vehicle can lead to increased fuel consumption as the engine works harder to move the extra weight. On the other hand, operating significantly below the MPC can also result in reduced fuel efficiency due to suboptimal engine performance.

What are the legal consequences of exceeding maximum payload capacity?

+Exceeding the maximum payload capacity can result in various legal consequences, including fines, vehicle impoundment, and even license suspension for the driver. These penalties are designed to deter unsafe practices and ensure compliance with safety regulations.